Whether operatives or management, Leading Edge gives your entire team the training and expertise to complete your jobs at height. On time. On budget. And with unprecedented safety.

Thousands of people choose Leading Edge height safety training every year. And it's not just because relevant bodies like the HSE recognise our courses. But it helps to know you'll be awarded license ID's and certificates you can rely on.

We don't just deliver a course. We work together to find the right work methods and height safety equipment to get you to The Edge — based entirely on your personal needs and access requirements.

Need height safety training on site? No problem! We'll travel to you with the necessary equipment to deliver your course. You can also visit us and enjoy huge discounts on open-enrolment or in-house training.

Don't settle for generic online training. We shape your course with information, images, equipment and work methods unique to your trade — that way you're guaranteed to get the most valuable and relevant skills for your job.

A Leading Edge course isn't a 'tick-in-the-box' laptop presentation. Because to be a Leading Edge instructor takes years of hard work, study and in-field experience. What you get is a dedicated height safety expert able to solve any height access challenge.

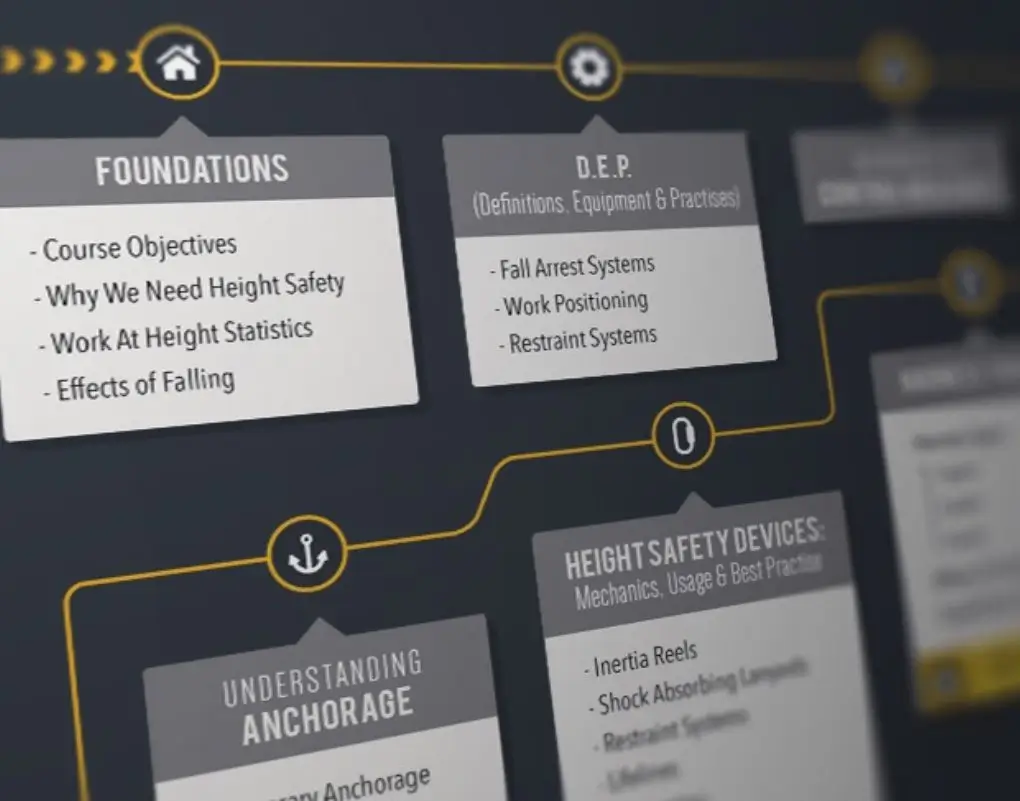

Legislation, control measures, equipment performance, work methods — there's a lot to learn. Sound daunting? We understand. That's why we've broken down everything you need to know into digestible modules. They're easier to absorb and scalable — so if certain topics concern you more than others, we can be as deep or as brief as you need.

After the theory training you need to prove your competency. To do that you'll sit a short multiple-choice exam that shows us you've absorbed everything you've been taught. The test papers are taken back to HQ and independently marked by a third party — and that's how we guarantee your certification meets the necessary legal requirements.

See what people just like you have to say about their experience with Leading Edge working at height safety and rescue training.

* Total number of people trained by Leading Edge as of Jun 20, 2023.

Copyright 2025 Leading Edge Safety. Devloped by Czargroup Technologies